Continuous Production Marking

Continuous Production Marking: Ensuring Efficiency and Traceability

Continuous production marking is a critical process in manufacturing that involves applying labels, codes, or stamps to products as they move along the production line. This ensures traceability, quality control, and regulatory compliance across various industries, including food, pharmaceuticals, and automotive manufacturing.

Key Aspects of Continuous Production Marking:

Product Identification: Each item is marked with batch numbers, barcodes, or QR codes for tracking.

Quality Assurance: Ensures products meet safety and authenticity standards.

Regulatory Compliance: Helps businesses adhere to industry regulations and legal requirements.

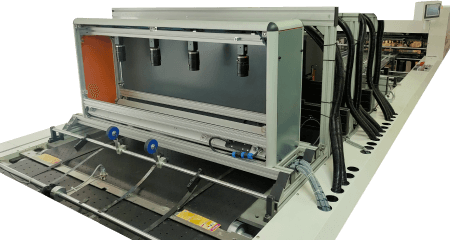

Efficiency and Automation: Automated marking systems reduce human error and increase production speed.

Benefits of Continuous Marking:

Reduces errors in product identification.

Enhances traceability throughout the supply chain.

Prevents counterfeiting with unique product codes.

Improves production efficiency with automated systems.

With modern laser, inkjet, and thermal transfer technologies, continuous marking helps manufacturers maintain high standards of quality, safety, and efficiency in today’s competitive market.